We had a whirlwind day here! Mr. Skellie and I were invited to a cookie swap and tea party at Marlene's house. Mr. Skellie was so excited that he was going to get to see Marlene that he was hopping all around the shop. He spent alot of time in front of the mirror...he wanted to look just right. While he was primping, I was baking cookies in the kitchen. He came flying in yelling, "I forgot about the cookies!" I told him not to worry, I would share the cookie dough with him. He got to work right away shaping some oatmeal raisin cookies but after only a dozen he said his hands were tired and he was going to take a break. He dug around in my china cabinet looking for something to put his cookies in saying that presentation was everything. He placed his cookies on one corner of the cookie sheet and kept a close eye on them while they baked.

When we arrived at Marlene's, he joined us at the table and showed off his cookies to the ladies.

He spent time with each lady flirting as usual. He laughed with Susie,

made googly eyes at Sharon....he especially liked her hair...

and sighed when he could at last spend time with his beloved Marlene.

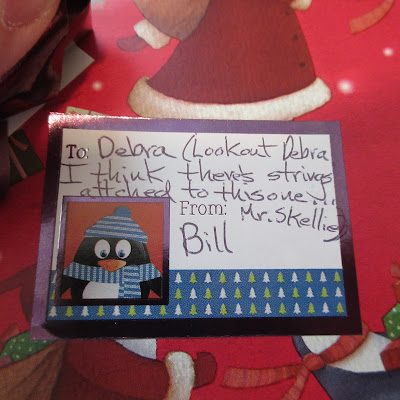

I think he's a party animal like his mother...her picture is on Mr. Skellie's Facebook page. After we had all finished our tea and ate more cookies than we should have, we said good-bye and headed home to wrap Christmas presents. The boxes were a little big for him to handle, so I put Mr. Skellie in charge of writing the tags for the gifts.

After he stuck them on the packages, I read a few and rolled my eyes.

He gets creative sometimes. I was getting ready to wrap some undies for myself and he was ogling the picture on the package.

"Is this what you will look like in these!? Wow!" he exclaimed. I told him to calm down and get back to writing tags. So this is the one he wrote for the undies...

Then he saw the undershirts I was wrapping for Bill...

"Whats with you guys and the underwear?" he asked. What can I say...we both needed some. Then he saw the funny surprise that arrived in the mail, so Mr. Skellie thought he would make friends.

I think he was just goofing off, just sayin'. When the last package was wrapped and put under the tree, I sat down and just enjoyed the lights and Christmas music playing and rested from all the things we accomplished.

Can't wait for Christmas! Have a great day!

Click on the pictures to make them larger

Thursday, December 21, 2017

Friday, December 15, 2017

Mr. Skellie's first Christmas Tree!

As I was adding finishing touches to our Christmas tree, I heard some rustling and grunting in the dining room. When I went to investigate, I found Mr. Skellie wrestling with his very own Christmas tree that he had found in one of the Christmas bins.

"Would you like a hand?" I asked. He asked if I could grab the light end and he would take the heavy end. Together we managed to get it upright and I helped him start fluffing up the branches. He started joking around and got tangled up in the branches

but I soon pried him loose. I showed him all the decorations for the tree and he was eager to start.

"Hey look, I'm a Christmas tree!" he yelled.

I turned and we both laughed. He was really enjoying his first foray into Christmas decorating. After he unwound himself, I helped him put it on his tree.

As he was hanging the first ornament, I noticed the tattoo.

"I thought that washed off during the last rainstorm you were caught out in..." I said. "I've been using that coverstick you have to cover it up..." said Mr. Skellie. "You mean the one I used to use to cover my eye bags...I've been wondering where that went..."I said. He said he feels like Popeye when he lets it show. I told him Popeye had arms that were a whole lot bigger but he came back with the comment that the bones were the same size. You can't win when you try to argue with a plastic skeleton I guess. We continued working on the ornaments together and after it was all done, I saw him looking at the tree and thinking.

"What's wrong?" I asked. "It needs lights...." he said. "Oh poopy, we'll have to take everything off the tree to do that and I'm not sure if I have any lights that will fit this tree." I said. I went to the shop and pulled out boxes and bins looking for the lights I had purchased on sale quite awhile ago. I found them and the batteries were still good!

Mr. Skellie approved. He helped me put them on the tree after we had taken all the ornaments and garland off. It was worth it to see how happy it made him.

Everything was put back on and I helped him with the ornaments that were up high.

He freaked out a little when I got the ladder out to reach the top, but I was careful and there were no accidents. "Why is there still an ornament left in the box?" he asked. I told him that was the star for the top and would he like to put that on. He grabbed it and I held him while he carefully put it on the top branch.

I explained to him that this star represented the one that shone in Bethlehem over the baby Jesus. He reflected on that quietly for a moment and then asked If I could get a good shot of his first tree...he wanted to remember it for always. (This is the "arty " shot he wanted...)

When night fell, I took another shot of it lit...

Mr. Skellie can't wait for Christmas! Have a great day!

"Would you like a hand?" I asked. He asked if I could grab the light end and he would take the heavy end. Together we managed to get it upright and I helped him start fluffing up the branches. He started joking around and got tangled up in the branches

but I soon pried him loose. I showed him all the decorations for the tree and he was eager to start.

"Hey look, I'm a Christmas tree!" he yelled.

I turned and we both laughed. He was really enjoying his first foray into Christmas decorating. After he unwound himself, I helped him put it on his tree.

As he was hanging the first ornament, I noticed the tattoo.

"I thought that washed off during the last rainstorm you were caught out in..." I said. "I've been using that coverstick you have to cover it up..." said Mr. Skellie. "You mean the one I used to use to cover my eye bags...I've been wondering where that went..."I said. He said he feels like Popeye when he lets it show. I told him Popeye had arms that were a whole lot bigger but he came back with the comment that the bones were the same size. You can't win when you try to argue with a plastic skeleton I guess. We continued working on the ornaments together and after it was all done, I saw him looking at the tree and thinking.

"What's wrong?" I asked. "It needs lights...." he said. "Oh poopy, we'll have to take everything off the tree to do that and I'm not sure if I have any lights that will fit this tree." I said. I went to the shop and pulled out boxes and bins looking for the lights I had purchased on sale quite awhile ago. I found them and the batteries were still good!

Mr. Skellie approved. He helped me put them on the tree after we had taken all the ornaments and garland off. It was worth it to see how happy it made him.

Everything was put back on and I helped him with the ornaments that were up high.

He freaked out a little when I got the ladder out to reach the top, but I was careful and there were no accidents. "Why is there still an ornament left in the box?" he asked. I told him that was the star for the top and would he like to put that on. He grabbed it and I held him while he carefully put it on the top branch.

I explained to him that this star represented the one that shone in Bethlehem over the baby Jesus. He reflected on that quietly for a moment and then asked If I could get a good shot of his first tree...he wanted to remember it for always. (This is the "arty " shot he wanted...)

When night fell, I took another shot of it lit...

Mr. Skellie can't wait for Christmas! Have a great day!

Monday, December 11, 2017

Stuff and Nonsense...

The day started quietly enough...I was enjoying my breakfast and giving thanks for my warm home on this very chilly Monday.

I heard a big commotion in the shop and lots of yelling and then Mr. Skellie came running into the kitchen all out of breath and screaming something about butterflies and committing suicide. I calmed him down and carried him into the shop with me. There was a bare spot in the butterfly arrangement

and a beautiful pink butterfly lying motionless on the floor.

Mr.Skellie checked his vital signs and I checked to see if anything was broken and assured Mr. Skellie that the butterfly was alright. When he woke up, he explained that he was having a wonderful dream about flying and lost his grip on the wall. As he is from the Cardstock family, he is very sturdy and asked if I could help him back with his fellows. Mr. Skellie had to sit down after the ordeal and Marlene brought him some sweet tea. Disaster averted! So, what was I saying? Oh, Bill was working on some doors for the birdseed cabinet and was crawling around with his head inside the cabinet putting on new hinges and such. They came out beautiful!

And this is what is stored in there...oh, the shelf is new too!

I was busy making turkey pie from scratch and since I had pastry leftover and pumpkin too, I made a pumpkin pie along with it.. Bill finished before I did so pulled out the vacuum and started in...with his kneepads still on! What a guy!

When we were both done, we enjoyed the turkey pie together and wandered out to the porch to check out the neighbor's Christmas lights.

The moon added the final touch, don't you think? Then yesterday, I pulled out the Christmas tree and Bill helped me carry all the Christmas bins in from the shed. It always looks like a Charlie Brown tree when I first put it up,

but once I am done with it, I will share the final result. Have a great day!

I heard a big commotion in the shop and lots of yelling and then Mr. Skellie came running into the kitchen all out of breath and screaming something about butterflies and committing suicide. I calmed him down and carried him into the shop with me. There was a bare spot in the butterfly arrangement

and a beautiful pink butterfly lying motionless on the floor.

Mr.Skellie checked his vital signs and I checked to see if anything was broken and assured Mr. Skellie that the butterfly was alright. When he woke up, he explained that he was having a wonderful dream about flying and lost his grip on the wall. As he is from the Cardstock family, he is very sturdy and asked if I could help him back with his fellows. Mr. Skellie had to sit down after the ordeal and Marlene brought him some sweet tea. Disaster averted! So, what was I saying? Oh, Bill was working on some doors for the birdseed cabinet and was crawling around with his head inside the cabinet putting on new hinges and such. They came out beautiful!

And this is what is stored in there...oh, the shelf is new too!

I was busy making turkey pie from scratch and since I had pastry leftover and pumpkin too, I made a pumpkin pie along with it.. Bill finished before I did so pulled out the vacuum and started in...with his kneepads still on! What a guy!

When we were both done, we enjoyed the turkey pie together and wandered out to the porch to check out the neighbor's Christmas lights.

The moon added the final touch, don't you think? Then yesterday, I pulled out the Christmas tree and Bill helped me carry all the Christmas bins in from the shed. It always looks like a Charlie Brown tree when I first put it up,

but once I am done with it, I will share the final result. Have a great day!

Friday, December 1, 2017

It's curtains for you!

You may remember a couple of months ago that I moved my shop to the bigger bedroom. The smaller room became the new office. My sister-in-law made a beautiful quilted wall hanging for my husband for his birthday and it made the perfect curtain for the window in there.

But you know me, it needed something more...I asked my sister-in-law where she purchased the fabric and went to see if I could find it. Whew! Quilt fabric is a regular investment now! After my wallet was considerably lighter, I came home with my 2 yards of starry material. Since the butterflies are up, the valance for the office window was the next project to clear out of my shop. Valances are just rectangles, but seem to require alot of math....

I don't want to math this early in the morning! I figured out what all the hems would have to be and how much material I needed and started in. I ironed the side hems first and then went to use my sewing machine.

Guess what, the foot pedal refused to work. I checked the plug and the wire and then Mr. Skellie came over to take a look. "How long has it been since you used it last?" he asked. I said probably a year or more. "No wonder it doesn't work, I bet all the electricity is stuck somewhere in the wire....maybe you should put some oil on the prongs of the plug so the electricity will slide easier inside the cord..." he said.

"You really think that will work?" I asked. I'm usually a pretty game gal, but that didn't sound quite right to me so I kept playing with the pedal. I finally found that if I took my shoe off and pushed on the pedal with my heel instead of my toes that it would work.

Hey, whatever works...So after considerable ironing and stitching, progress was being made.

Mr. Skellie was trying his best to help, but almost got himself stitched into the curtain.

Had to do some more math

and found that I had miscalculated so just kind of winged it from there. Mr. Skellie was really proud of our accomplishment

and now the window dressing is complete!

Have a great day!

But you know me, it needed something more...I asked my sister-in-law where she purchased the fabric and went to see if I could find it. Whew! Quilt fabric is a regular investment now! After my wallet was considerably lighter, I came home with my 2 yards of starry material. Since the butterflies are up, the valance for the office window was the next project to clear out of my shop. Valances are just rectangles, but seem to require alot of math....

I don't want to math this early in the morning! I figured out what all the hems would have to be and how much material I needed and started in. I ironed the side hems first and then went to use my sewing machine.

Guess what, the foot pedal refused to work. I checked the plug and the wire and then Mr. Skellie came over to take a look. "How long has it been since you used it last?" he asked. I said probably a year or more. "No wonder it doesn't work, I bet all the electricity is stuck somewhere in the wire....maybe you should put some oil on the prongs of the plug so the electricity will slide easier inside the cord..." he said.

"You really think that will work?" I asked. I'm usually a pretty game gal, but that didn't sound quite right to me so I kept playing with the pedal. I finally found that if I took my shoe off and pushed on the pedal with my heel instead of my toes that it would work.

Hey, whatever works...So after considerable ironing and stitching, progress was being made.

Mr. Skellie was trying his best to help, but almost got himself stitched into the curtain.

Had to do some more math

and found that I had miscalculated so just kind of winged it from there. Mr. Skellie was really proud of our accomplishment

and now the window dressing is complete!

Have a great day!

Wednesday, November 29, 2017

Pies and Butterflies!

Ahhh, Thanksgiving! We spent it with family and had a wonderful time. My brother and sister-in-law played host and hostess in their lovely home and we ate and laughed and were so grateful for each other. We came home and decided we were going to cook a turkey on the following Sunday. We ended up having a whole Thanksgiving meal together, just me and my Dear Hubby. When I was cooking a pie that morning, I decided to try a new crust recipe I saw on Facebook. It's here: No Fuss Pie Crust I followed the directions and mixed it up. It felt kinda tough but I soldiered on. You were supposed to be able to press it into your pie plate, but it was not behaving itself.

Ahhh, Thanksgiving! We spent it with family and had a wonderful time. My brother and sister-in-law played host and hostess in their lovely home and we ate and laughed and were so grateful for each other. We came home and decided we were going to cook a turkey on the following Sunday. We ended up having a whole Thanksgiving meal together, just me and my Dear Hubby. When I was cooking a pie that morning, I decided to try a new crust recipe I saw on Facebook. It's here: No Fuss Pie Crust I followed the directions and mixed it up. It felt kinda tough but I soldiered on. You were supposed to be able to press it into your pie plate, but it was not behaving itself.Mr. Skellie came into the kitchen and between the 2 of us, it finally resembled pie crust.

Filled it with pumpkin pie filling, and baked it until it was done.

After it was cool, it was time to taste test it. My pie crust recipe is easy to cut, so I was surprised when I had to cut and chop it to free the first piece.

I didn't have the same luck with the second piece.

The crust had good flavor, but it was crunchy and fell apart easy. I think I'll go back to rolling out my pie dough, I like a more tender crust. However, I still ate it....;) Today, I finally found myself in my shop staring down all these butterflies.

I guess I really should stick them on the wall over the curtain, they have been waiting for quite some time now. They came with little stickers that I stuck on each one.

I started putting them up, and began having fun doing it.

So here they are, a Kaleidoscope of butterflies!

Have a great day!

Subscribe to:

Posts (Atom)